An Eco-Friendly Solution for Conversion of Infectious Waste

Traditional off-site waste treatment has a lot of downsides

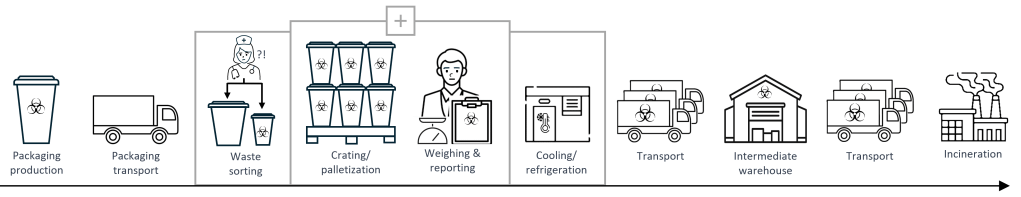

Ordinary infectious waste handling requires waste to be treated outside the hospital, often at a distant incineration plant. Downsides include:

- High costs for packaging, cooling, transportation, and treatment

- Administrative burden from reporting

- A lack of refrigeration space can quickly arise if waste collection is delayed

- High CO2 emissions – no potential for recycling

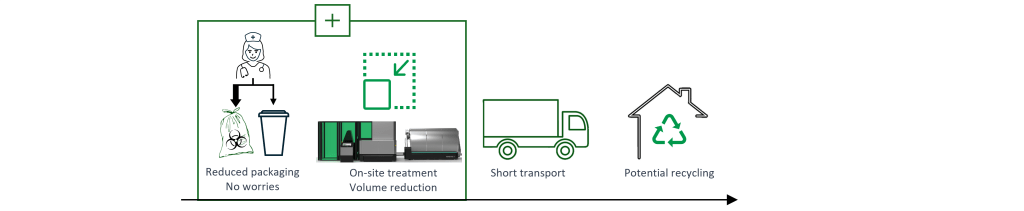

You can now enjoy the benefits of on-site treatment

By treating and shredding infectious waste at the hospital you can:

- Limit packaging needs

- Facilitate waste sorting

- Reduce administrational burdens and risk exposures

- Improve resilience by not being dependent on external service providers

- Minimize waste miles and facilitate potential recycling

See video below for further comparison (please turn sound on)

A safe, cost-effective, and eco-friendly solution

Naslund X9 is a patented product. The X9 process consists of the following steps:

- Waste carts are elevated and emptied into a robust shredder that cuts the material into small pieces.

- These small fragments are then transferred into a cylindrical processing chamber.

- When the chamber’s inlet have been sealed, ozone in high concentration is introduced into the chamber, during which the material is continuously agitated. This ensures every piece is exposed to the same concentration of ozone, powerfully oxidizing and killing/inactivating pathogens.

- Subsequently, the waste is vacuumed out of the chamber and directed to the client’s container or compactor after which the material can be handled as non-risk material.

Ozone, O₃, has been employed commercially for over a century. Its purification capabilities are well-established, particularly for air and water disinfection. The X9 produces ozone on-site from ambient air. After the disinfection process, any residual ozone is safely and effectively converted back to oxygen, leaving behind no environmentally harmful by-products.